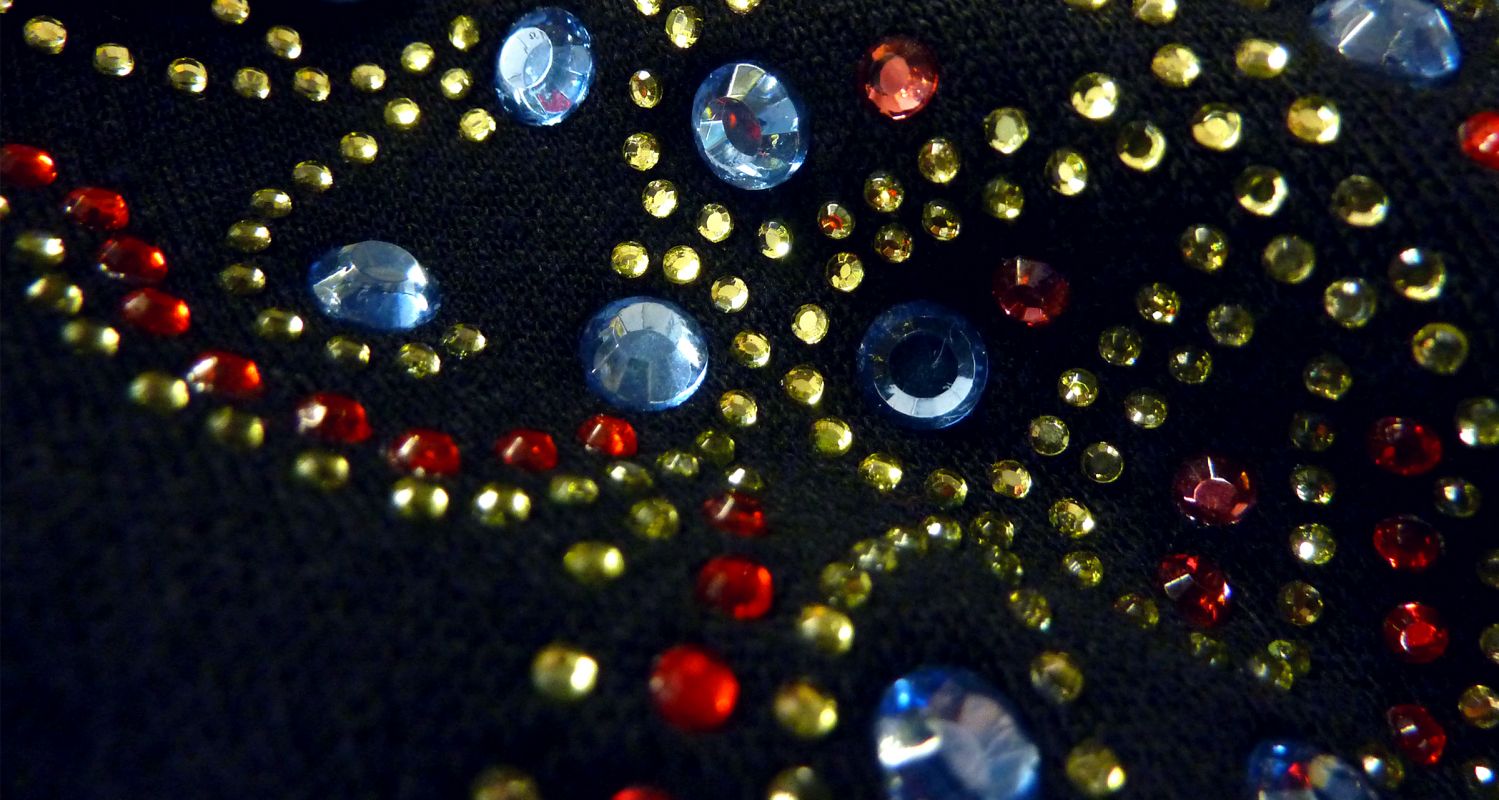

Thermo-adhesive woven labels are an ideal accesory both to repair clothing and to personalize or customize garments. Easy to apply and fun to combine with other elements from the world of fashion and creativity, they come in various shapes, they can be shield-type, classic shapes such as square, rectangular, circular, triangular, etc.

Manufacturing

Unit: minimum 300 units

Application parameters

Temperature: 170-180ºC

Pressure: Medium (4 bars)

Time: 12 seconds

Paper removal: no need

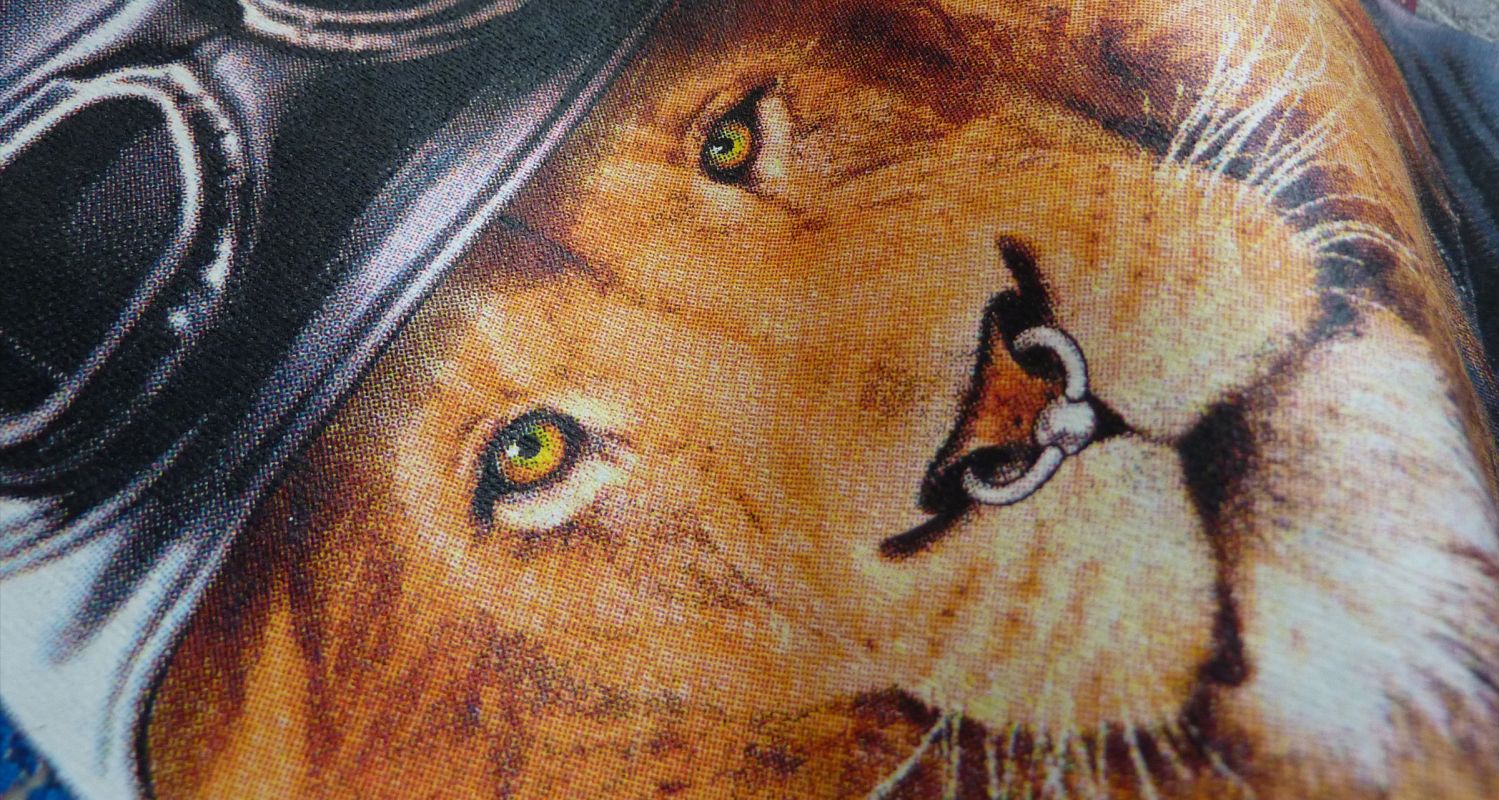

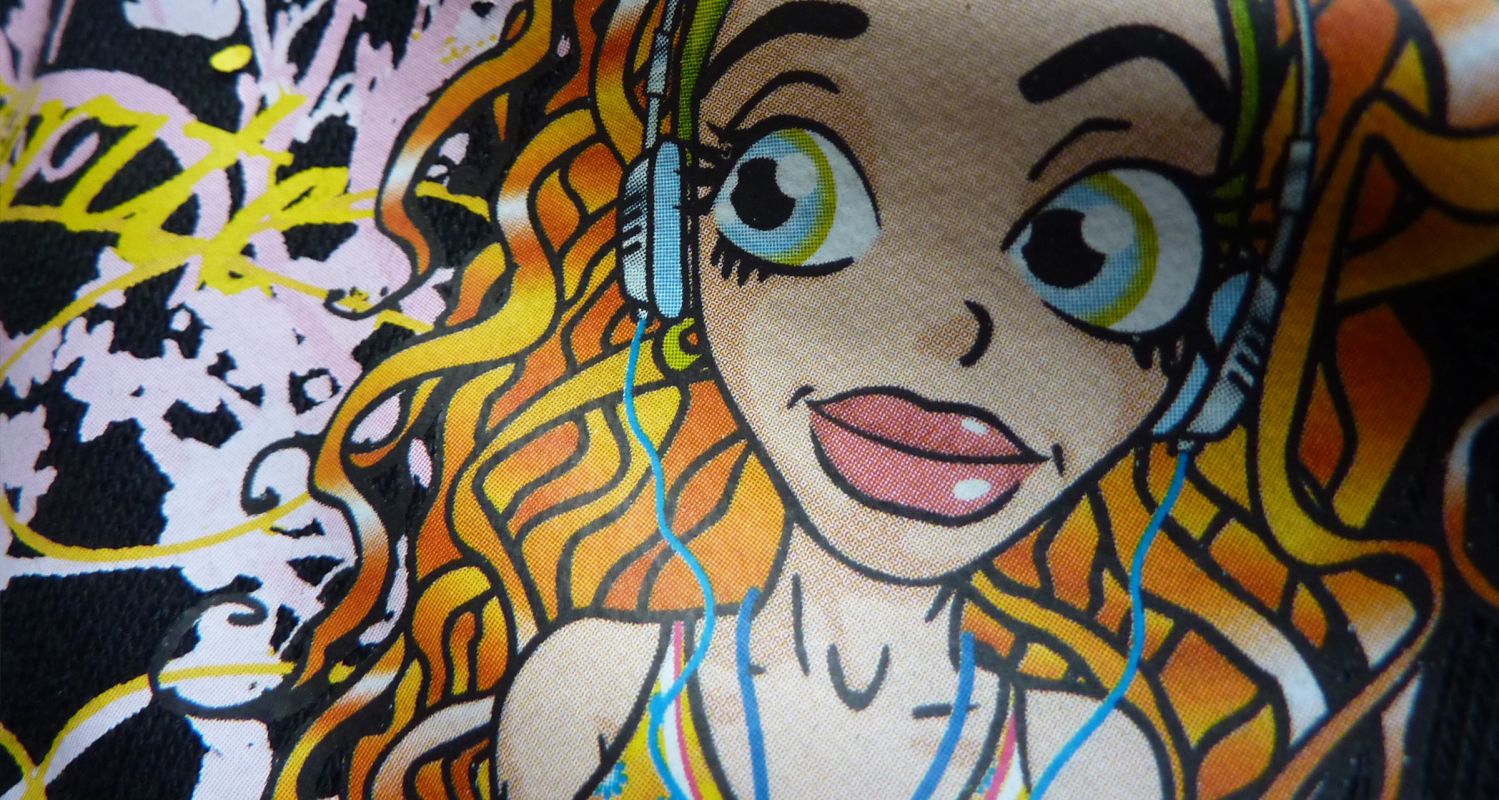

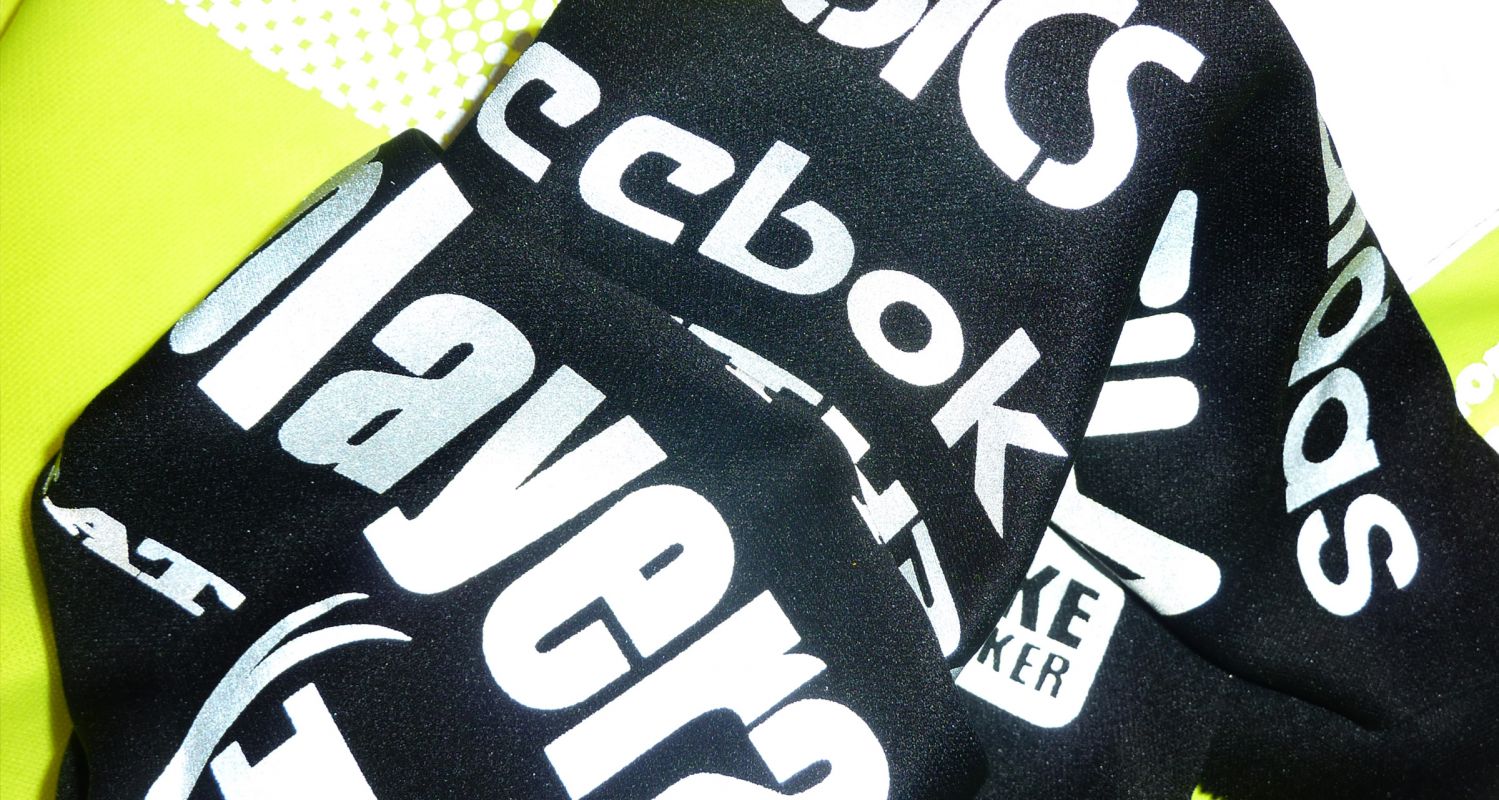

Fabric heat transfer design and printing at JMB

For the manufacture of the fabric heat transfer, they are made from 300 units per model. With regard to the subsequent printing on the fabric, a medium pressure between 175º and 180º and for approximately 8 to 10 seconds should be applied. No need to remove any foil at the end of the process!

At JMB we work with a team of designers and printing professionals who can help you create the most original designs with the fabric heat transfer technique. Due to its versatility and speed, you will obtain a collection of ready-to-wear garments in a short time. And always with a guarantee of quality and resistance! Contact us for more details.