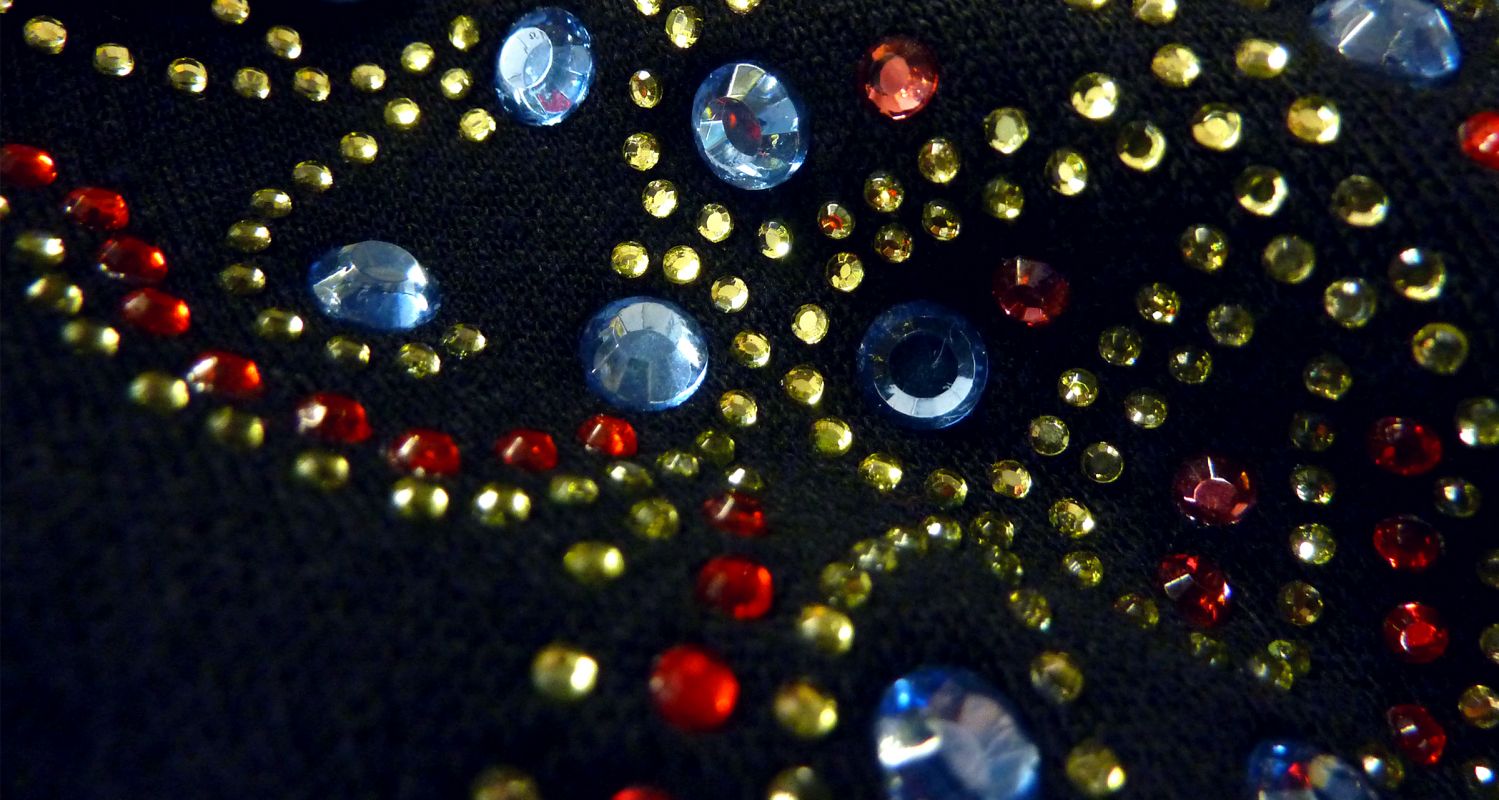

The puff heat transfer has an unmistakable finish among all types of printing techniques, since it achieves a puffed effect on the ink and allows relief to be applied in those areas that want to stand out. Due to these very particular characteristics, it is recommended to print them only on textile garments that are 100% cotton or mixed with synthetic fibers, but never on elastic fabrics such as nylon or those with special finishes.

Manufacturing

70x50cm sheet: minimum of 50 sheets

90x60cm sheet: minimum 300 sheets

Application parameters

Temperature: 170-180ºC

Pressure: Medium-High (5-6 bars)

Time: 8 seconds

Paper removal: hot

Design and Printing of the puff heat transfer in JMB

At JMB we are specialists in the manufacture of different techniques, including the heat transfer in puff. If you are looking for a very visual and textured finish, this is yours!

To obtain a quality result, the temperature applied must be between 170º and 180º, with medium-high pressure and hot paper peel. In less than 8 seconds you will have your transfer puff design ready for use!

If you are interested in getting your transfers with this technique or you want them printed on textiles or equivalent, at JMB we have both machinery and garments as well as a team of professional designers. Contact us!